In January of 2011, the FDA’s Food Safety Modernization Act (FSMA) was signed into law. FSMA is the most sweeping reform in food safety in over 70 years. It is designed and aimed at preventing contamination rather than responding to it. This is the basis of why understanding as well as a practice in food safety is not only important; it is now required by law. More on FSMA here.

STEP 1: All breweries needed to register by December 31, 2012. Online registration can be completed HERE. Failure to register can result in the FDA’s enforcement of the law potentially stopping a food producer from producing as well as seizure of all products.

The publication of the final rules has been released and the compliance deadlines can be found here.

This new compliancy act applies only to domestic and foreign facilities that manufacture, process, pack, or hold food for human or animal consumption in the U.S.A. which fall under FDA jurisdiction. As you may already know, it’s the Alcohol and Tobacco Tax and Trade Bureau (TTB) that monitors the alcoholic beverage industry. Despite their current jurisdiction, the TTB has the authority to involve the FDA in cases of tainted batches of beer. Under FSMA, food processing facilities will be inspected by the FDA for compliance. The TTB and the FDA acknowledge breweries are subject to FDA inspection.

The FDA is now working to specifically define the regulations for all food facilities to implement as written preventative control plans.

So, what specific objectives should breweries be targeting? The MBAA Food Safety website has been designed to provide a roadmap on types of programs that are required for compliance.

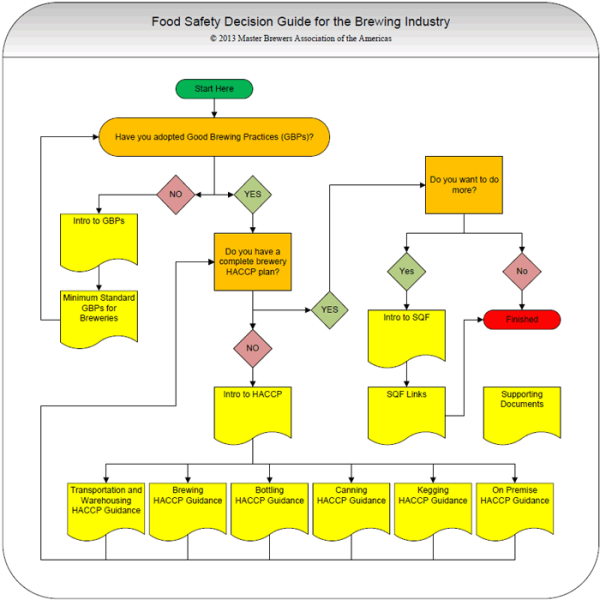

One of these tools includes a decision tree which can help determine what phase is most relevant depending on the current state of compliance in the brewery. Without a doubt the foundation of any food safety program starts with GMPs (Good Manufacturing Practices), and in the case for breweries these are also called GBPs (Good Brewing Practices) as well.

One of these tools includes a decision tree which can help determine what phase is most relevant depending on the current state of compliance in the brewery. Without a doubt the foundation of any food safety program starts with GMPs (Good Manufacturing Practices), and in the case for breweries these are also called GBPs (Good Brewing Practices) as well.

GBPs promote hygiene and cleanliness that helps ensure a cleaner and safer environment for employees and ensure products are produced, handled and stored under safe and sanitary conditions. These practices can improve safety and well-being of employees while reducing the chance of pest infestations, and other costly risks that could result in a business being shut down due to public health hazards. There are many third party auditing firms that help companies comply with regulatory or industry standard GBPs. The MBAA has released a document template for breweries to utilize: the “Minimum GBP Requirements for Breweries.” This is an excellent starting point on which to build, so that the policies and standards become suited to match the needs of the brewery.

Once GBPs are in place the next step for a brewery is to undertake a detailed study of the product and process in order to identify existing or needed food safety control measures to control food safety hazards. This process is called Hazard Analysis and Critical Control Points (HACCP). It is a risk assessment tool widely used by the food industry to identify and control food safety hazards which could result in a consumer’s illness, injury, or death. FSMA bases the requirements for the written food safety plan on the HACCP principles (ref. FSMA Current Good Manufacturing Practice and Hazard Analysis and Risk-Based Preventive Controls for Human Food and preventive Controls for Animal Foods).

But instead of calling it HACCP, FSMA refers to Hazard Analysis and Risk Based Preventive Controls (HARPC). It is a subtle but important difference. HARPC aligns with HACCP in the design, development, implementation, and verification of the food safety plan required by FSMA. The primary difference lies in the designation of the preventive controls. Under HACCP these would typically be restricted to those steps identified as CCPs whereas under HARPC there is no such restriction. This should encourage facilities to review their entire operation in a more holistic manner by managing all of the controls in place regardless of how they are classified (e.g., GBPs, CCPs, or other designations) and should allow facilities to better create food safety controls which reflect hazards within their operations.

Therefore, it is imperative that the industry accepts the needs and specific requirements under FSMA. Failure to comply does not come with just a slap on the wrist. Requirements for reverification through follow-up inspections come at the cost of several hundred dollars per hour. Additionally, if facilities are continuously found non-compliant, they can have their rights to produce suspended and management face criminal prosecution.

In 2015, MBAA launched HACCP training for brewery operations to help the brewing industry understand the requirements for GBPs, HACCP, FSMA, and how they all fit together. For more information on this course, click here.